What is the chemical compatibility of PVC Tubing? What are the characteristics of PVC Tubing?

2022-06-09|

Table of Contents |

Chemical Compatibility of PVC tubing

The following information is based on the chemical compatibility of plastic tubing listed in the 2019 edition of the Good Gi Catalogue, including the chemical compatibility of PVC tubing. This chemical compatibility guide must not be compatible with previous or future catalogue editions, bulletins or in conjunction with any other compatibility guidelines in the publication. The chemical compatibility of plastic tubing may change from time to time due to changes in the manufacturing process. Incorrect use of these charts may result in personal injury or property damage.

How to determine the chemical compatibility of the chemicals listed in Good Gi PVC Tubing:

-

Locate the Material Code in the Material Code Table.

-

Locate the media to be carried or the chemical the PVC tubing will be exposed to in a Media to Plastic Tubing Material Compatibility Table and read the rating code (G, L, P, “-”, “#”) under the material column.

-

Look up the rating code in the Rating Codes Table.

Material Code Table

| GOODGI Thermoplastic Tubing P/N | Material | Code |

| - | High Density Polyethylene | HDPE |

| - | Flexible Nylon | N |

| GPA | Unplasticized Nylon (semi-rigid) | NR |

| - | Linear Low Density Polyethylene | PE |

| GHT, GDW | Flame Resistant Polyethylene | PEFR |

| GR | Polypropylene | PP |

| GP-100, GP-200, GP-300, GP-600 | Flexible Polyvinyl Chloride (PVC) | PV |

| - | Polyurethane | U |

| - | Fluorinated Ethylene Propylene | FEP |

| - | Perfluoroalkoxy | PFA |

| GND-LL, GND-SS, GND-TT | Polytetrafluoroethylene | TFE |

| GKY | Polyvinylidene Fluoride | PVDF |

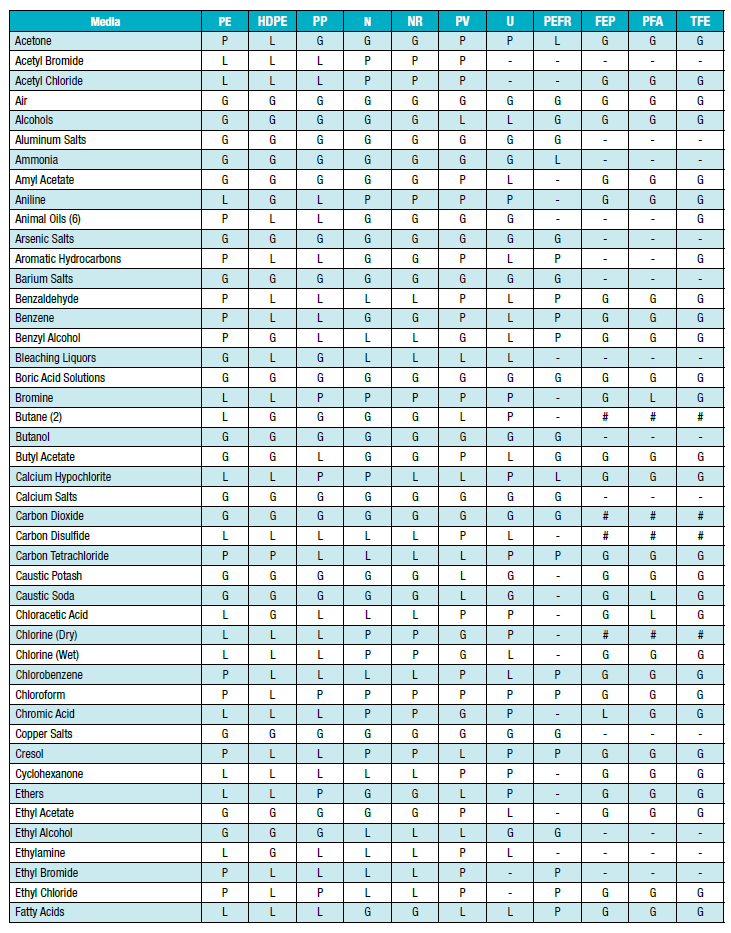

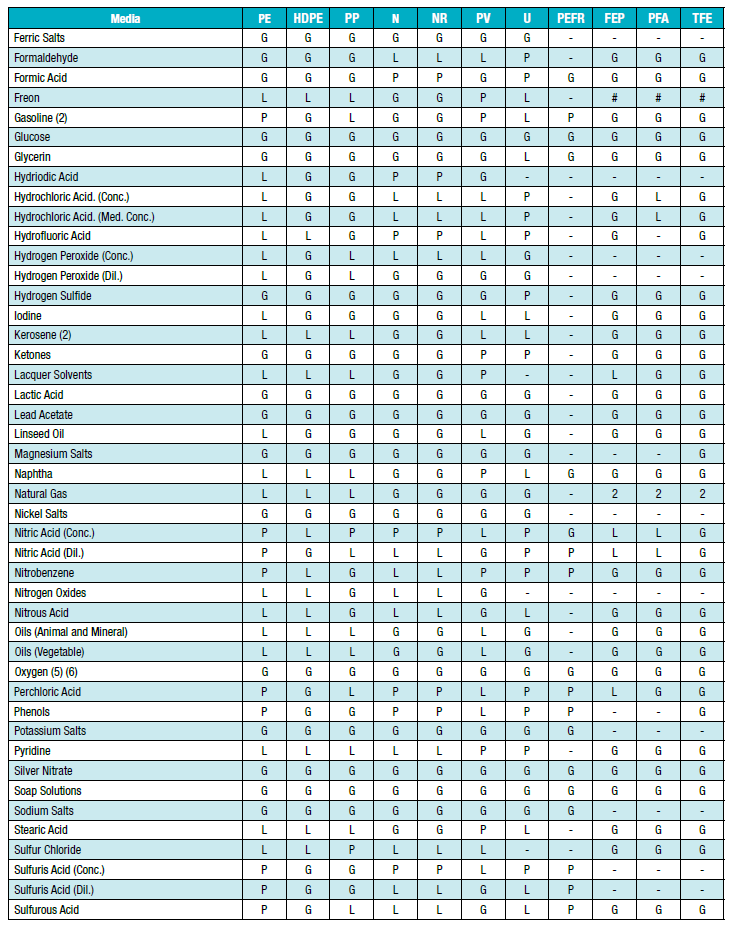

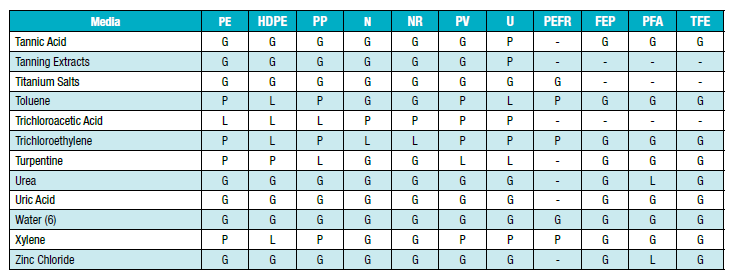

Media and PVC Tubing Materials for Chemical Compatibility Table:

Compatibility Ratings Codes Table

-

G:Good to Excellent - Little or no swelling, tensile or surface changes. Preferred choice.

-

L:Marginal or Conditional - Noticeable effects but not necessarily indicating lack of serviceability. Further testing suggested for specific applications. Long-term effects such as stiffening or potential for crazing should be evaluated.

-

P:Poor or Unsatisfactory - Not recommended without extensive and realistic testing.

-

-:Not tested - Compatibility not known.

-

#:For fluoropolymer - Indicates good chemical resistance but potential for excessive permeation.

Introduction of raw materials of PVC Tubing

The raw material of PVC tubing is polyvinyl chloride(abbreviation: PVC)is a polymer material obtained by addition polymerization of vinyl chloride. It is the world's third-most widely produced synthetic polymer of plastic(after polyethylene and polypropylene)

Chemical structure of PVC- -CH_{2}-CHCl-CH_{2}-CHCl-CH_{2}-CHCl-

There are two basic forms of PVC processed into tubing:rigid and flexible. Rigid tubing PVC such as water pipes. Flexible Tubing is made more flexible by adding plasticizers (most commonly phthalates). In this form, it can be used to extrude (extrude) hoses, cable jackets, etc., and replace rubber in many applications, and the PVC tubing produced by Good Gi is this kind of flexible form.

What are the characteristics and applications of PVC tubing

-

Voltage Resistance

-

Weather Resistance

-

High And Low-Temperature Resistance

-

Flex Resistance

-

Oil Resistance

It is widely used in insulation and protection of automobile wiring harness, motor and wire connection parts.Although PVC tubing contains halogens, its excellent aging resistance makes them difficult to replace in harsh environments.

相關產品

| Photo | Product Name | Rated voltage | Operating Temp. | Remark |

|---|---|---|---|---|

|

Extruded PVC Tubing

GP-600V

|

600V | -30℃~105℃ | UL Certification |

|

Extruded PVC Tubing

GP-300V

|

300V | -30℃~105℃ | UL Certification |

|

Cold Resistance Extruded PVC Tubing

GP-600V-CR

|

600V | -40℃~105℃ | UL Certification |

|

NO UL Extruded PVC Tubing

GP-100

|

customized | -10℃~100℃ | NO UL Certification |

|

PVC Blank Marker Tubes

GMOR

|

- | -10°C~100°C | RoHS Certification |