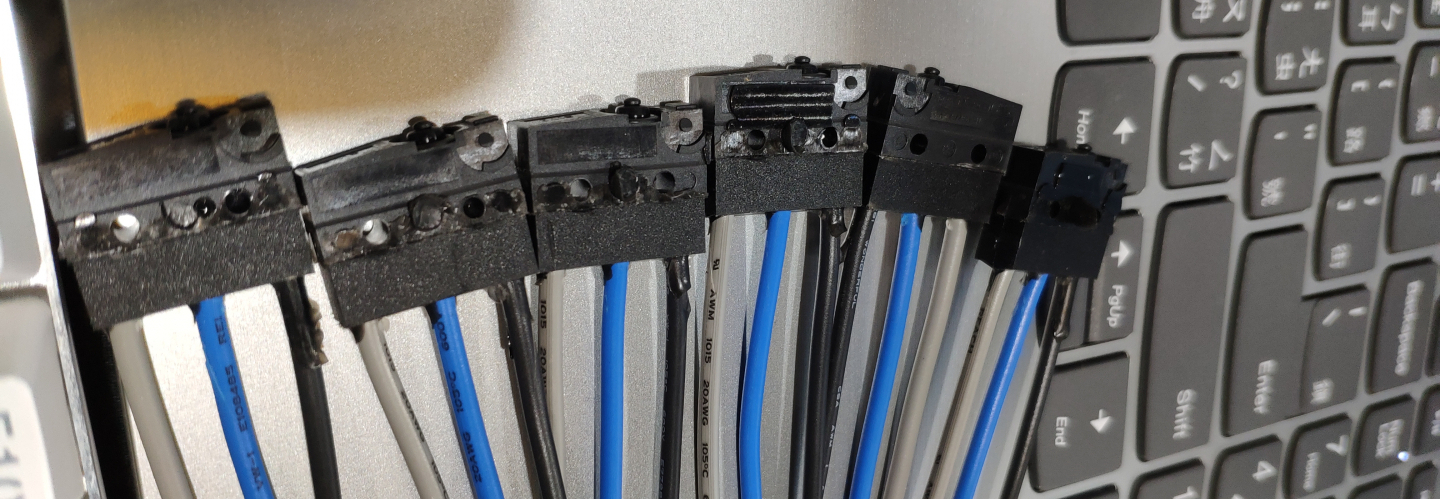

การฉีดแรงดันต่ำที่ใช้ในไมโครสวิตช์

2021-06-28เมื่อปลายปี 2019 บริษัทจดทะเบียนซึ่งผลิตไมโครสวิตช์และอุปกรณ์จ่ายไฟในเมือง Shulin ประเทศไต้หวันเป็นเวลาหลายปีได้ติดต่อมาที่เรา

บุคลากรด้านการวิจัยและการพัฒนาได้มอบหมายให้เราช่วยวิเคราะห์สาเหตุความล้มเหลวของชุดไมโครสวิตช์ภายใต้การทดสอบในสภาพแวดล้อมที่อุณหภูมิสูง จากการวิเคราะห์เชิงทดลองภายใน พบว่ามีสาเหตุมาจากการยึดเกาะที่ไม่เพียงพอระหว่างกาวร้อนละลายแบบฉีดแรงดันต่ำกับตัวหลักของใยแก้ว PBT+30%

หลังจากการทดสอบโดยช่างเทคนิคแล้ว วัสดุฉีดแรงดันต่ำ KY-8807 และใยแก้ว PBT+30% มีการยึดเกาะดีขึ้นและคุณสมบัติกันน้ำที่ดีกว่า เป็นไปตามมาตรฐาน IP67 มีคุณสมบัติทนต่ออุณหภูมิสูงในระยะยาว ทนต่อแรงดันไฟฟ้าสูงและมีความแข็งปานกลางทำให้เหมาะสำหรับการดัดลวด

8807/8807A โพลีเอไมด์ฉีดขึ้นรูปด้วยความดันต่ำเป็นเม็ดฉีดเทอร์โมพลาสติกแรงดันต่ำที่มีส่วนประกอบเดียว มีความเหนียวที่อุณหภูมิต่ำ มีช่วงอุณหภูมิการใช้งานที่กว้าง และการยึดเกาะที่ดีกับพื้นผิวต่างๆ ไม่กัดกร่อน ไม่เป็นพิษ ไม่มีกลิ่น ไม่มีสารอันตรายเกิดขึ้นระหว่างการใช้งานและสารหน่วงไฟเป็นไปตามมาตรฐาน UL94 V-0 สามารถให้ฉนวนกันความร้อน ทนต่ออุณหภูมิ กันน้ำ กันฝุ่น ทนต่อแรงกระแทก ดูดซับแรงกระแทก ทนต่อการกัดกร่อนของสารเคมี เป็นต้น